Both systems unite to produce accurate, efficient, and reliable results for production and manufacturing purposes.

The robotic system has revolutionised the manufacturing industry, enabling it to produce top quality products efficiently, accurately, and consistently.

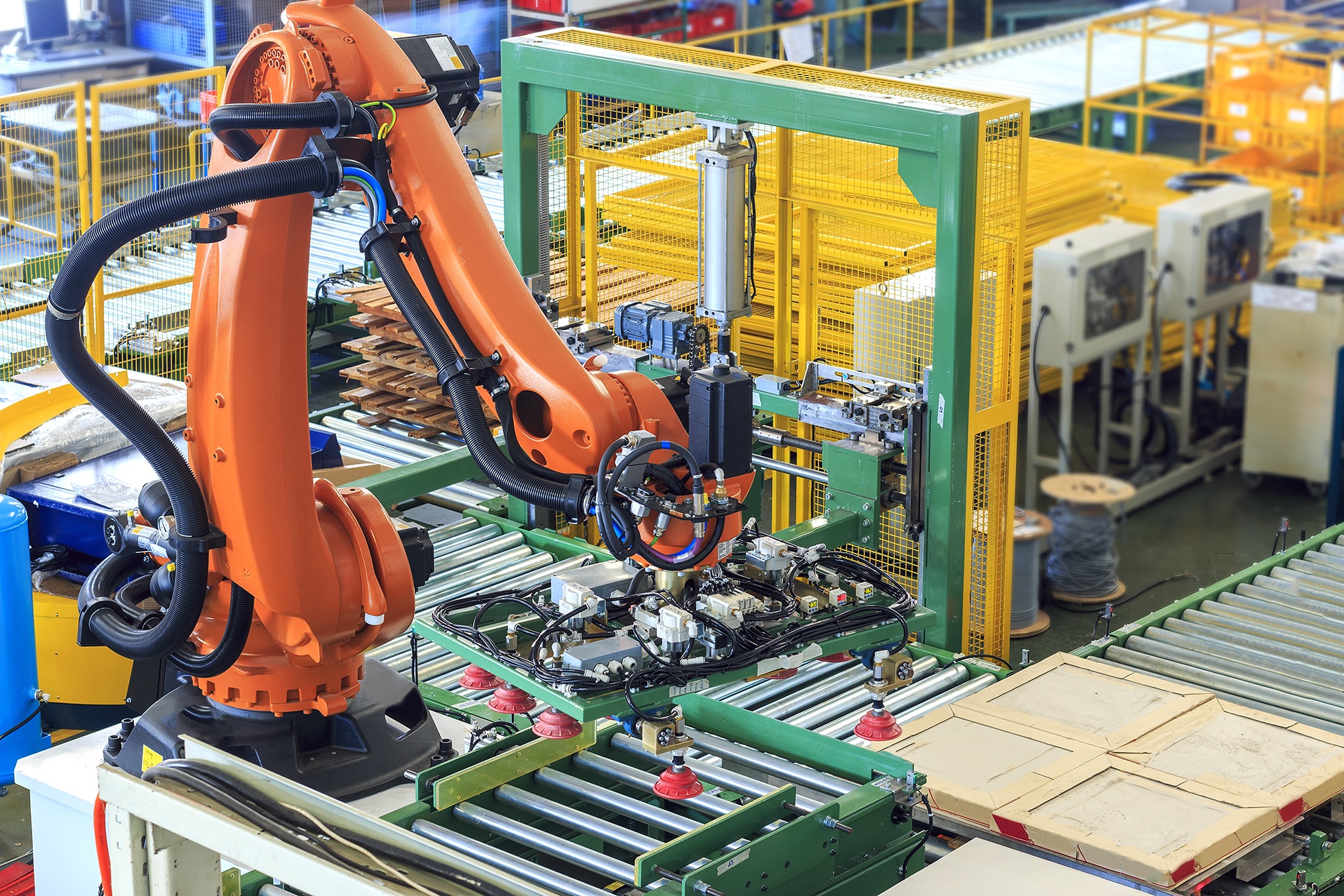

There are two common types of robotic systems used in the manufacturing and production industries. The manipulation robotic system and the mobile robotic system. Over the years, we’ve installed various solutions which have increased productivity and improved production quality, including a robotic paint system.

A conveyor system advances production by transporting various objects of all weights, shapes, and sizes from one operating stage to another.

All types of conveyors have specialised strengths and operational purposes, depending on the requirements of the production or environment.

A robotic conveyor system unites the advantages of both these systems to create the most productive, accurate and reliable results. Every solution can be custom-built to accommodate all types of operating purposes and manufacturing environments, such as robotic arm conveyor belts.

Integrating robotic conveyor systems

At Hills Electrical Group, we understand that time is money. Our team can work at a time that suits you best to ensure downtime is minimised.

The process of integration unites robotics with conveyor systems into a seamless single production system. Installing integrated robotic conveyor systems will lower costs, improve product quality, reduce production time, and enable your best workers to focus their efforts on other areas.

Integration is simple through easy programming and compatible conveyor system technology. Our team maintain the entire process to advance your production demands without the need for delay.

The biggest benefits of robotic conveyor systems

-

- Leveraging two innovative systems into one operating unit

- High return on investment

- Top-quality production results

- Efficient, accurate and consistent production

- Reduce labour costs

- Minimise human error and workplace injuries

As a UK specialist in robotic conveyor systems, you can trust us with your investment. Our solutions and services are first-class. We supply custom-built robotic conveyors that will advance your operations no matter the specifications, from robot arm conveyor belts to automated robot paint systems

If you require any advice on conveyor systems, please get in touch. One of our friendly specialists will be happy to share their expert guidance.

To discover more recent conveyor-related information and updates, please follow us on LinkedIn.